Inauguration of a new plant dedicated to the manufacture of innovative concrete blocks

On October 21 and 22, 2020, the brand new Perin & Co. plant was inaugurated. Located in Saint Maudez, this facility is the 3rd Air’Bloc® plant.

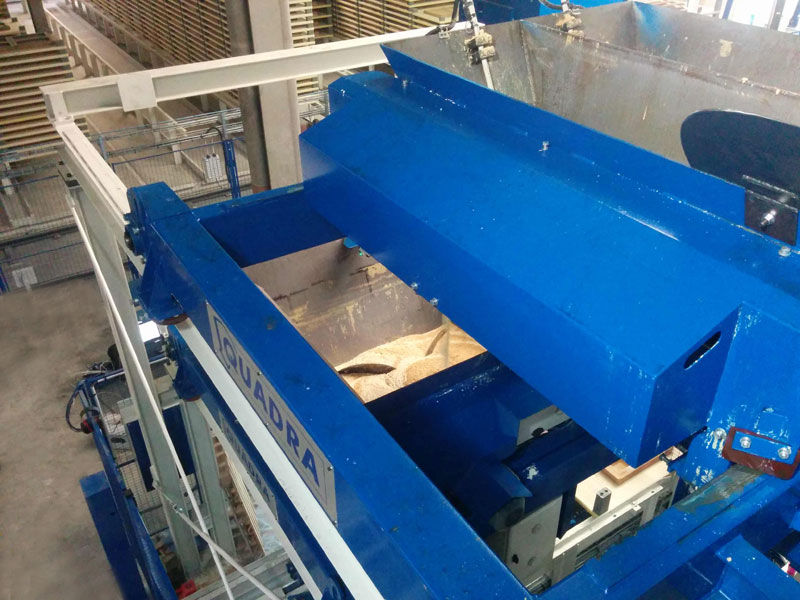

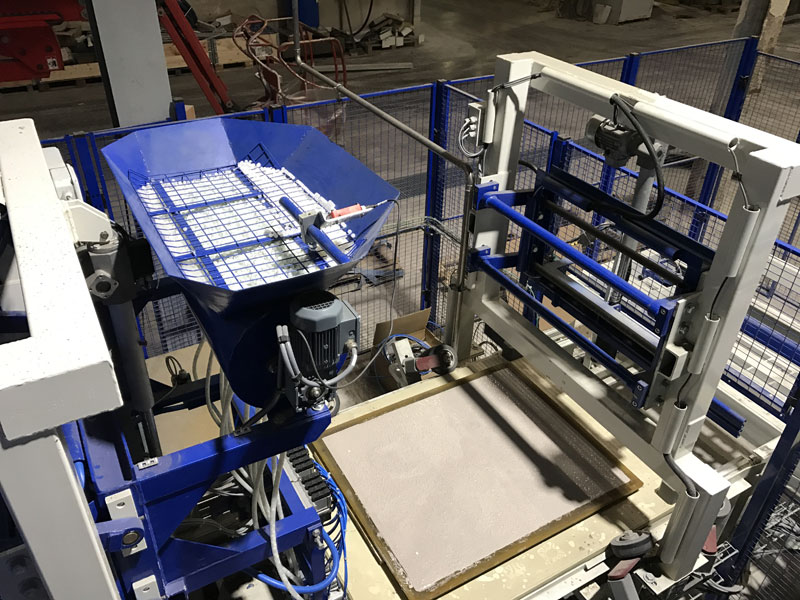

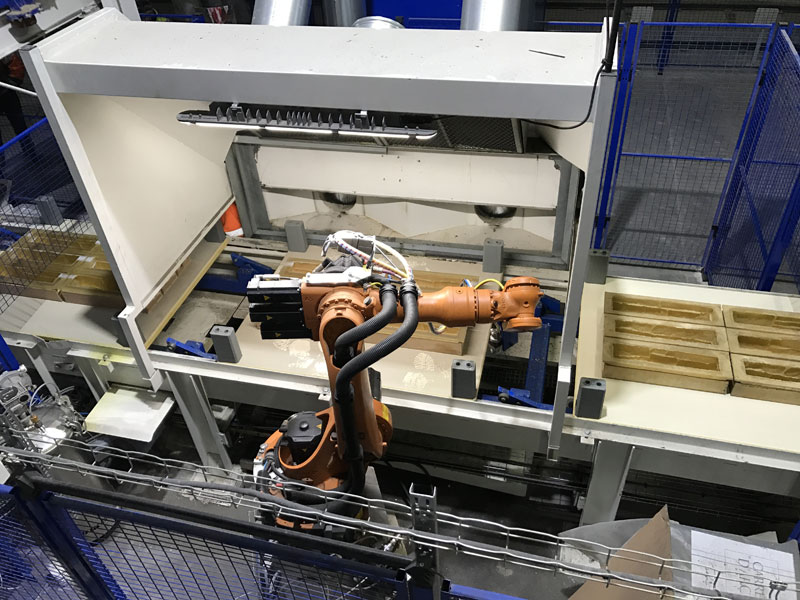

established in France. In 2014 Perin & Cie will design and develop the Air’Bloc. It is the combination of a concrete block and an all-mineral cement-based insulating foam called Air’Mousse. To generate the insulation, Air’Mousse, patented by Perin & Co., a special filling machine must be installed. This machine is the result of a 3-year collaboration between Quadra and the Perin & Co. group.

Collaboration between Quadra and Perin & Company

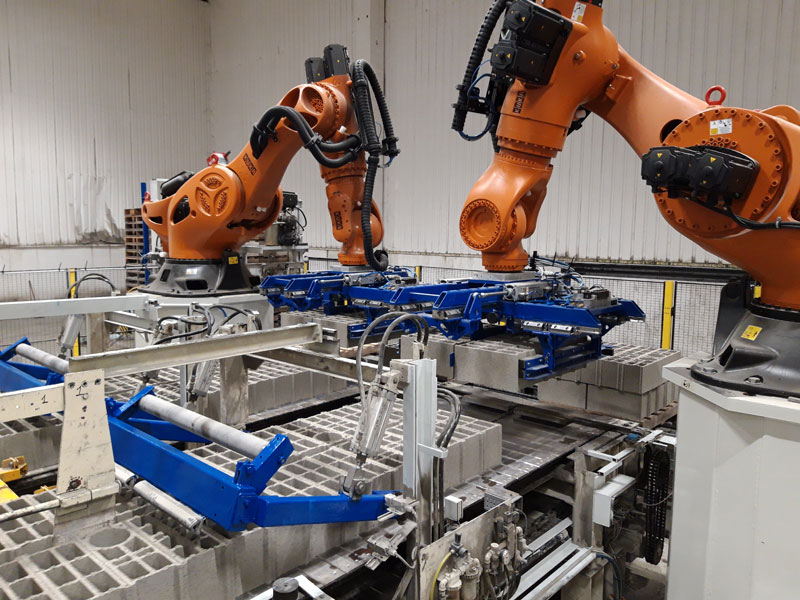

As an industrial partner, Quadra participates in the development of Air’Bloc installations, provides innovative equipment, while improving existing production lines. As part of its new investment in Saint-Maudez, it was important for Perin & Co. that their partner was able to meet precise specifications. Thanks to its technical expertise and after an in-depth study of the various aspects of the project, Quadra was able to provide an appropriate response.

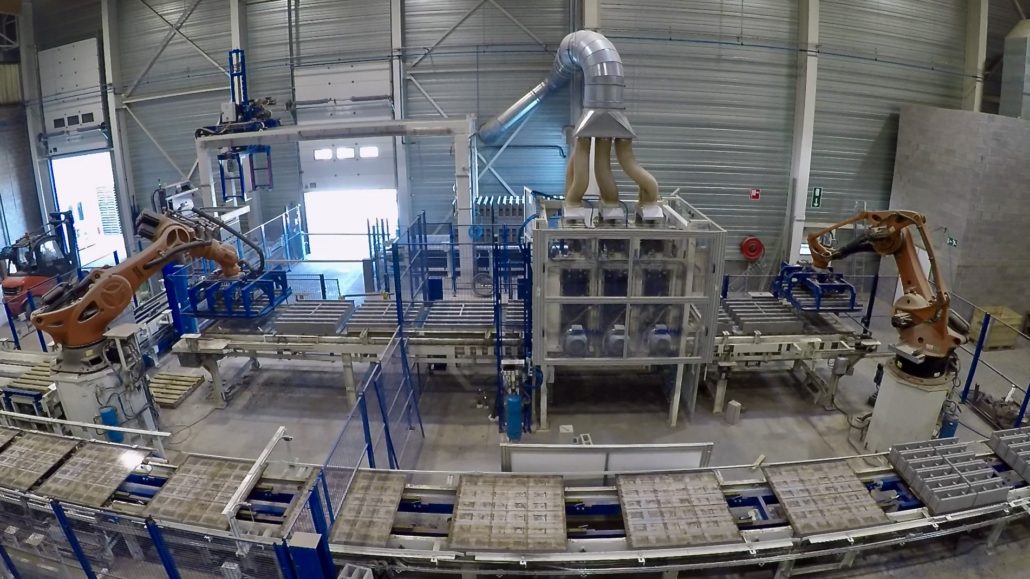

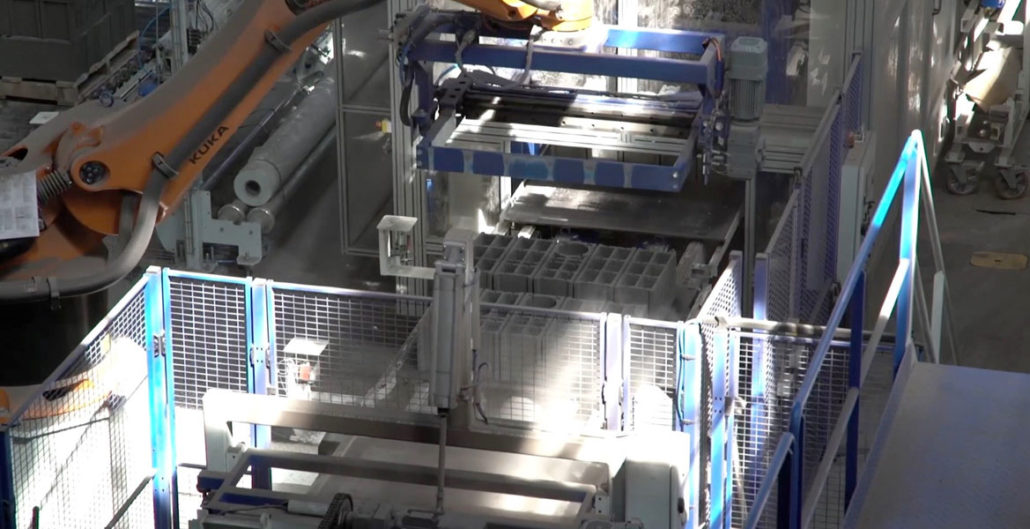

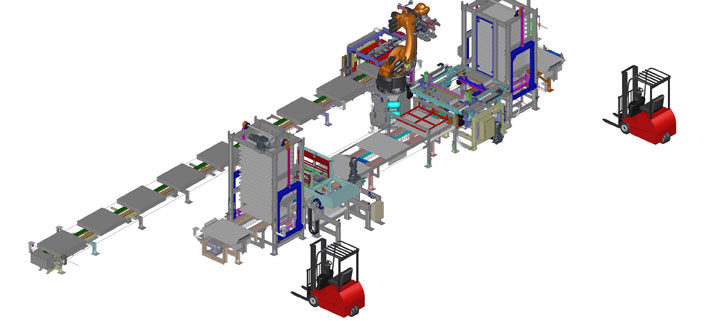

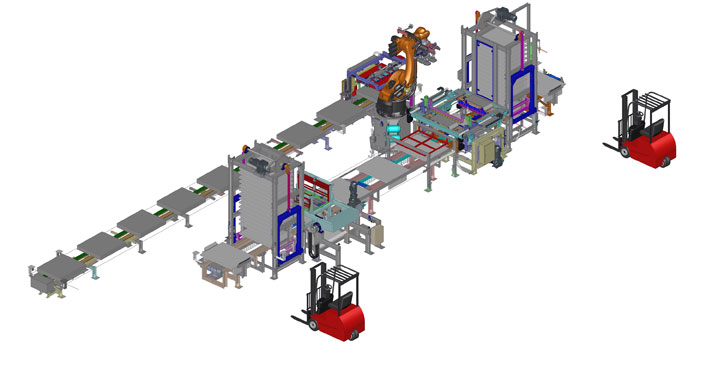

Plant layout

Given the particularity of the Air’Bloc® manufacturing process, the equipment was installed in a rational and functional manner. This layout allows each stage of the manufacturing process to operate simultaneously and continuously. With its different equipments, this versatile production unit can produce classic blocks, rectified blocks and high quality Air’Bloc®.