Modernization at Heinrich & Bock facilities: two new Quadra high-performance vibrating presses installed

Collaboration between Heinrich & Bock and Quadra began as part of the modernization project for the Wittenheim and Steinbourg facilities. Looking for a reliable and technologically advanced partner, Heinrich & Bock’s management was quickly attracted by the innovative dimension and versatility of the equipment offered by Quadra.

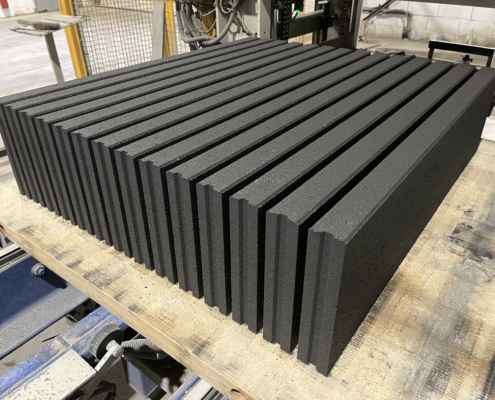

Regarding the Wittenheim site, the new block making machine had to be able to use the new wooden boards with dimensions of 1,400 x 1,200 mm. and a thickness of 50 mm and also to reuse all the moulds for pavers, kerbstones and accessories from the block making machines currently in operation at the Krautergersheim and Wittenheim sites without any adaptation. In addition, all concrete products such as hollow blocks, hourdis, slabs, paving stones, kerbstones and landscaping products had to be manufactured. The Q12 HP block making machine, whose technology, features and performance meet the requirements in every respect, was the model proposed and chosen to meet these objectives.

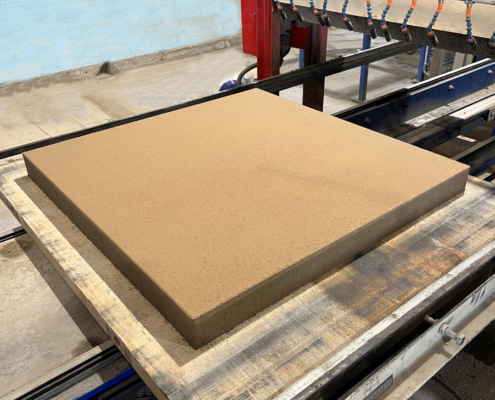

For Steinbourg site, specifications were particularly delicate to implement, given the requirements to be met and the constraints linked to the existing infrastructure. The block making machine installed had to be able to use wooden boards dimensioned 1,200 x 650 mm with a thickness of 40 mm and had to be compatible without adaptation with an already existing large mould set for a product height of 40 to 400 mm. In view of these requirements, a Q5 block making machine with two-layer equipment was proposed and chosen for the project. This production unit is particularly intended for the manufacture of high-quality products with high added value.

Read more about this installation in our new CPI article!