As an expert in automated processes and vibration systems, Quadra designs and builds turnkey production machines for manufacturing a wide range of concrete products such as blocks, pavers, slabs, curbs, fences, and more. Its latest-generation, innovative, and versatile equipment is sold both in France and worldwide. At bauma 2025, the French manufacturer presented its latest technological breakthroughs.

Tag Archive for: Vibrating press

As an expert in automated processes and vibration systems, Quadra designs and builds turnkey production machines for manufacturing a wide range of concrete products such as blocks, pavers, slabs, curbs, fences, and more. Its latest-generation, innovative, and versatile equipment is sold both in France and worldwide. At bauma 2025, the French manufacturer presented its latest technological breakthroughs.

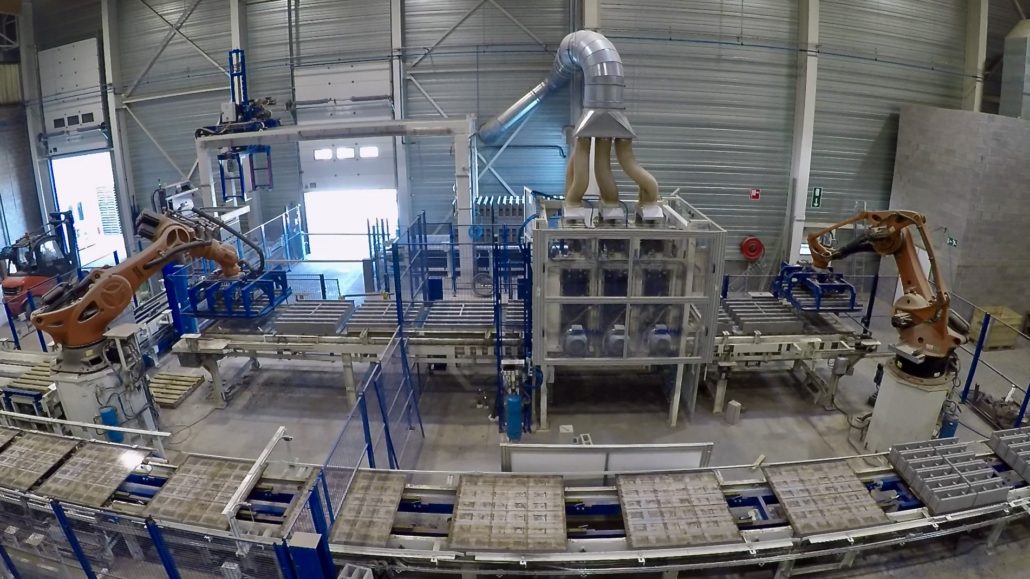

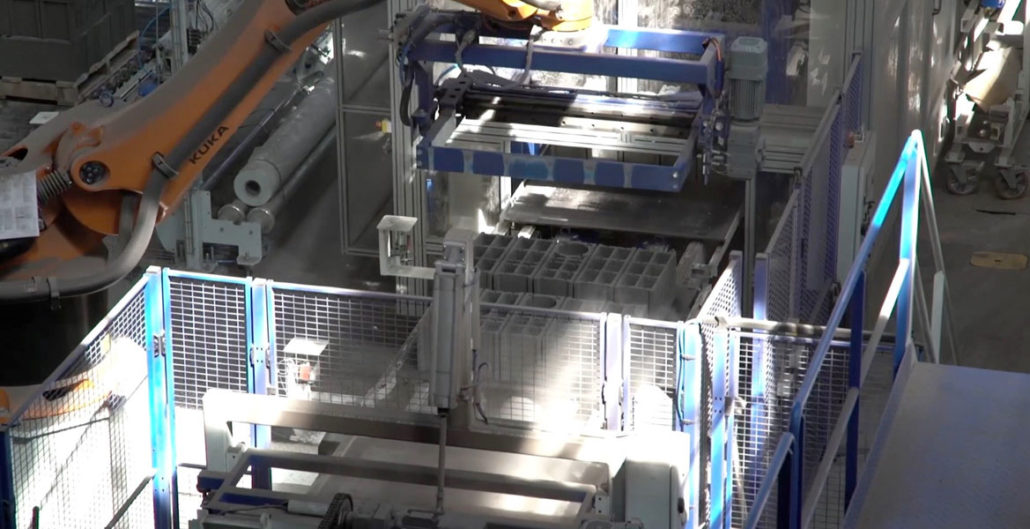

Recently, as part of the modernisation of its Neumarkt site, Kann chose to equip the plant with a robotised palletising system to replace the old conventional equipment. Quadra, a French manufacturer of automated equipment for the concrete industry, supplied the new facility.

With Lithosys, the Vicat Group aims at becoming a major player in concrete 3D printing both on the French and international markets. To support the unit in the continual enhancement of this innovative technology, Vicat has selected Quadra, the French equipment manufacturer for the concrete industry and an expert in automated processes, as partner.

Collaboration between Heinrich & Bock and Quadra began as part of the modernization project for the Wittenheim and Steinbourg facilities. Looking for a reliable and technologically advanced partner, Heinrich & Bock’s management was quickly attracted by the innovative dimension and versatility of the equipment offered by Quadra.

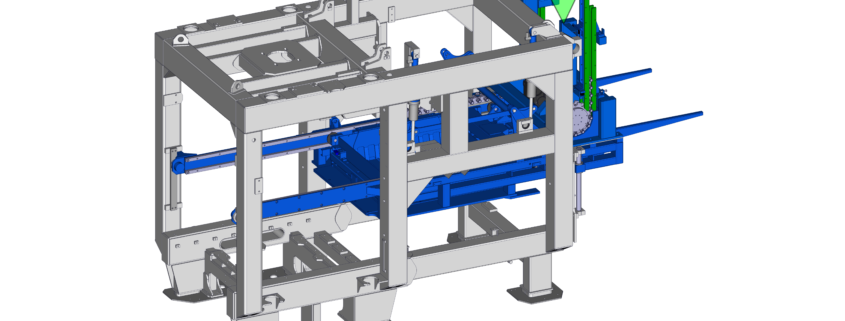

New concept of vibrating press with immediate demoulding characterized by the fact that this equipment can produce according to two different modes

of operation:

• A demoulding mode by turning the mould over

• A demoulding mode by raising the mould

This special vibrating press has thus the ability to manufacture a wide range of products. The production is fully automatic with particularly optimised industrial

production rates.

Inauguration of a new plant dedicated to the manufacture of innovative concrete blocks

On October 21 and 22, 2020, the brand new Perin & Co. plant was inaugurated. Located in Saint Maudez, this facility is the 3rd Air’Bloc® plant.

established in France. In 2014 Perin & Cie will design and develop the Air’Bloc. It is the combination of a concrete block and an all-mineral cement-based insulating foam called Air’Mousse. To generate the insulation, Air’Mousse, patented by Perin & Co., a special filling machine must be installed. This machine is the result of a 3-year collaboration between Quadra and the Perin & Co. group.

Collaboration between Quadra and Perin & Company

As an industrial partner, Quadra participates in the development of Air’Bloc installations, provides innovative equipment, while improving existing production lines. As part of its new investment in Saint-Maudez, it was important for Perin & Co. that their partner was able to meet precise specifications. Thanks to its technical expertise and after an in-depth study of the various aspects of the project, Quadra was able to provide an appropriate response.

Plant layout

Given the particularity of the Air’Bloc® manufacturing process, the equipment was installed in a rational and functional manner. This layout allows each stage of the manufacturing process to operate simultaneously and continuously. With its different equipments, this versatile production unit can produce classic blocks, rectified blocks and high quality Air’Bloc®.

The installation of this new plant had to meet very precise specifications both in terms of production performance and product quality. To meet the group needs, Quadra presented a solution capable of ensuring continuous operation of the vibrating press.

To achieve a high efficiency rate, simultaneous or independent production cycles have been proposed for the fresh products, the dry products and the packaging line:

- By ensuring at all times, the supply of the press with empty pallets to consume concrete continuously.

- By pre-storing a large quantity of dry products pallets, thus avoiding the presence and systematic intervention of an operator.

The handling solutions offered and the automated management of materials favoring the continuous operation of the vibrating press are the reasons why PREFER decided to renew their confidence in QUADRA for this new project.

During the last 10 years, the construction industry has been changing to technical products with high thermal, mechanical, acoustic, seismic and environmental performances. The concrete industry has been recently providing innovative products which combine technical reliability, aesthetic finishing, and easy implementation. These new products are largely approved by the manufacturers that are submitted to the new energetic and environmental regulations buildings. The concrete block is promoted, and regains market shares.

The company Pomel Beton, group Bomeil/Boulard Verdier since 2010, and member of the Groupement Gedimat, manufactures a large range of concrete products intended for industrial, residential, agricultural construction, and also used in the landscaping industry. Pomel Beton’s old production unit did not allow the manufacture of technical blocks or the use of new technologies. Therefore the group took on a strategic position in investing in technical installations provided by Quadra.

As part of this investment, the company Pomel Beton defined several specifications. More than a supplier, Pomel Beton was looking for a partner able to assist them in the manufacture of new value-added products such as a grinded block, and the insulation block “Air’Bloc’.

Following a strong investigation of all aspects of the project such as the existing environment, the current and future production requirements, and a rational implantation, Quadra provided the following equipment: batching and mixing plant, vibrating press, grinding machine, palletising robot, handling equipment, and dosing and filling system feeding the hollow block with a mineral foam for the manufacture of the product Air’Bloc.

QUADRA

40, route de Findrol

74130 Contamine-sur-Arve

France

+33 4 50 03 92 21

+33 4 50 03 69 97

info@quadra-concrete.com

QUADRA USA INC

One Renaissance Tower

2, North Central Avenue

Suite #1800

Phoenix, AZ 85004

États-Unis

(+1) 602 373 2951

info@quadra-concrete.com

HYDROSTOP

ZI Des Grands Bois

1, rue du Luxembourg

49280 Saint-Léger-sous-Cholet

France

(+33) 2 41 56 82 93

info@hydrostop.fr

www.hydrostop.fr